Keeping up the flow

by HANS-PETER OTT on Aug 6, 2024 10:00:00 AM

Flexible automation of material flow has great potential for productivity increases in industrial manufacturing. The new LCP AMR Top Module from Interroll can help, ensuring seamless interaction between autonomous mobile robots and stationary conveyors.

Skills shortages, high costs and competitive pressures – manufacturing companies are currently facing challenges on several fronts. Many are responding by further increasing their level of automation and making production ever more efficient. Autonomous mobile robots (AMR) are at the forefront of this shift. The rapidly changing process environments require particularly flexible conveyor solutions. These might, for example, be needed to supply production cells, assembly or packaging stations with an efficient material supply and removal, or to connect storage, picking and production areas. In addition to stationary conveyors, these transport tasks are increasingly being fulfilled by AMRs. Indeed, the market has great growth prospects: Experts expect global AMR sales to reach around US $220 billion (€201 billion) by 2030, with average annual growth of over 18 percent from 2020.

Recommended And Certified By Robotics Manufacturers

The LCP AMR Top Module, a new conveyor module within Interroll’s proven Light Conveyor Platform (LCP), is supporting this growth. It now gives system integrators the ability to integrate scalable belt conveyor lines and AMR applications into a single material-handling solution to quickly and easily meet their customers’ automation needs. And it is a proven solution – the module was extensively tested prior to launch by OMRON and MiR, two leading global AMR manufacturers, and recommended for use with their respective mobile robots. “With this modular platform solution, we are unlocking for our customers and users the great productivity potential that near-production automation of material flow offers,” says Stefano Amarena, Solution Sales Director Manufacturing Logistics, at Interroll. “The flexibility of this solution, the use of proven technologies and a very short payback period ensure that it can significantly strengthen our business partners’ competitiveness.

HOW INTERROLL HELPS MANUFACTURERS

Interroll’s modular conveyor handling solutions have been proving their worth to manufacturers for years, for example in the tire and automotive industries. The company’s conveyors and drives are used by leading global companies such as Michelin, Continental, Bridgestone, Pirelli, FCA, PSA, Ford, Jaguar and Toyota. In addition to compact plug-and-play concepts and quiet, energy-efficient operation, users appreciate the uncomplicated installation and low maintenance requirements, as well as the high reliability and operational safety of these solutions.

Our LCP Autonomous Mobile Robot (AMR) Top Module enables handling of lightweight goods on the AMR.

Simplified Functionality With Decentralized Controllers

However, the highlight of the Shepherdsville material handling solution is the intelligent control concept of the zero-pressureaccumulation conveyor system. This involves a decentralized machine control system, which Interroll’s multi-protocol-capable MultiControl controllers offer as standard as part of the MCP. It enables, for example, the sensors and the RollerDrive to be integrated directly into the fieldbus level. As a result, there is no need for an additional sensor/actuator level with extra gateways. Furthermore, the MultiControl’s intelligent conveying logic simplifies the design of a zero-pressure-accumulation conveyor based on a programmable logic controller (PLC). This reduces the resulting data traffic because only key decision points in the system need to be accessed at PLC level. The overall system can also be visualized on screens.

So what exactly does the LCP AMR Top Module do? The device is an innovative conveyor module that enables the automatic handling of goods. It consists of two parts: the top module, created based on Interroll’s extensive and long-standing experience with conveyors; and an adapter that acts as a connector between the top module and the AMR. The latter has a plug-and-play interface developed using Interroll’s expertise in machine control, enabling seamless and simple operation for the end user.

An Easy-To-Integrate Solution

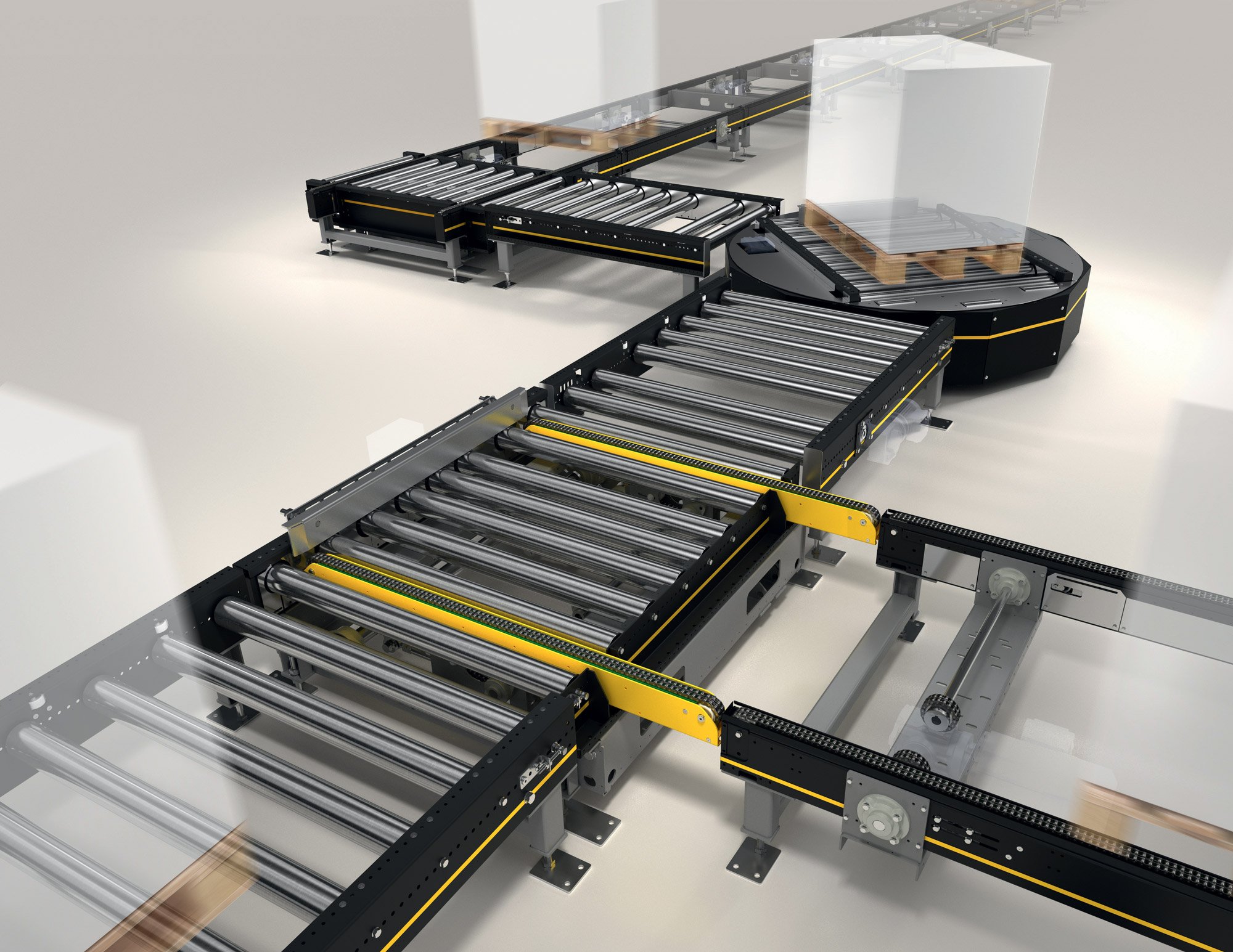

The module functions within Interroll’s proven LCP conveyor platform, which consists of factory-assembled and predefined modules. These can in turn be connected to other Interroll conveyor platforms, such as the Modular Conveyor Platform (MCP) or existing conveyors from other manufacturers. In this way, storage, sortation, picking and production areas, for example, can be very easily connected via an end-to-end automated material flow. As part of this complete modular solution, system integrators can now seamlessly and conveniently integrate AMRs into a comprehensive material-flow solution without any major engineering effort. In conjunction with Interroll’s popular Layouter tool, where planned solutions can be planned and put together very easily and conveniently on a PC, project run times and effort for system integrators are drastically reduced. In addition, users benefit from maximum process reliability, as all hardware and control components are fully coordinated with each other.

/header-mcp-reference-cookie-manufacturer-1.jpg?width=487&height=275&name=header-mcp-reference-cookie-manufacturer-1.jpg)

Interroll's Modular Conveyor Platform (MCP)

THE LCP AMR TOP MODULE

The Biggest Benefits At A Glance

COMPLETE SOLUTION FROM A SINGLE SOURCE

Users benefit from maximum availability and process reliability, as all hardware and control components are already matched.

PROVEN AND CERTIFIED TECHNOLOGIES

Tested and recommended by the world’s two leading AMR manufacturers, the conveyor module includes reliable components that have been proven hundreds of thousands of times. The LCP AMR Top Module was developed based on Interroll’s long-standing leadership in conveyor technology. An ESD-certified version for protection against electrostatic discharge is optionally available.

FLEXIBLE, SCALABLE AND MODULAR

As with all Interroll solutions, the modular platform concept allows mobile AMRs and stationary LCP conveyors to be added easily, flexibly and as needed.

COMMUNICATION, CONTROL AND SAFETY

An integrated, single-source control system provides a seamless connection between the AMR, the LCP AMR Top Module and a stationary LCP conveyor. A noncontact communication system from Interroll is used for the connection between the top module and the conveyor, as well as for the safe conveying of the goods.

Gain exciting insights into the VUCA world of today and the intralogistics scenario of tomorrow

Download our trend report

What are the challenges and trends in intralogistics in 2030? Download our trend report to learn more.

Interroll's specialists are here to answer all your questions about our modular material-handling solutions and deployment of AMRs:

You May Also Like

These Related Stories

A seamless solution

Distributed intelligence makes flow of goods fit for the future